Readouts / Comparators

Micro IIi Readouts

Western Gage Corporation’s Micro IIi Readouts Incorporate backlit LCD displays that flag out-of-tolerance conditions by changing color from green to red. Seven-decade digital displays show actual feature sizes or deviations from nominal sizes. They also include analog bar graphs to graphically display the test piece condition relative to the product limits. Auto-Zero and Auto-span setting features make these instruments very operator friendly. USB & RS-232C serial data and process control outputs are standard. AEQ-42-11-60 with blind air probe and master shown.

Micro IIi Readouts Multiple Channels & Displays

Multi-Channel Micro IIi Triple Display

- Available up to 4 Input Channels

- Available up to 4 Displays

- For Air Gages or LVDT or Both

(Micro IIi model AEQ 42-32N-60 shown)

Micro IIi Readouts for Taper Angles

- Configure to check Angular Deviations or

- Configure to check Contour Tolerances

(Micro IIi model AEQ 42-33M-60 shown)

Multi-channel Micro IIi Single Display

- Auto-Select models direct inputs to single display

- Automatically senses active gaging member

(Micro IIi model AEQ 42-14-60)

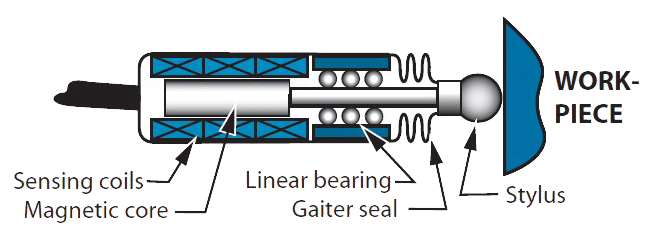

Linear Variable Differential Transformer (LVDT)

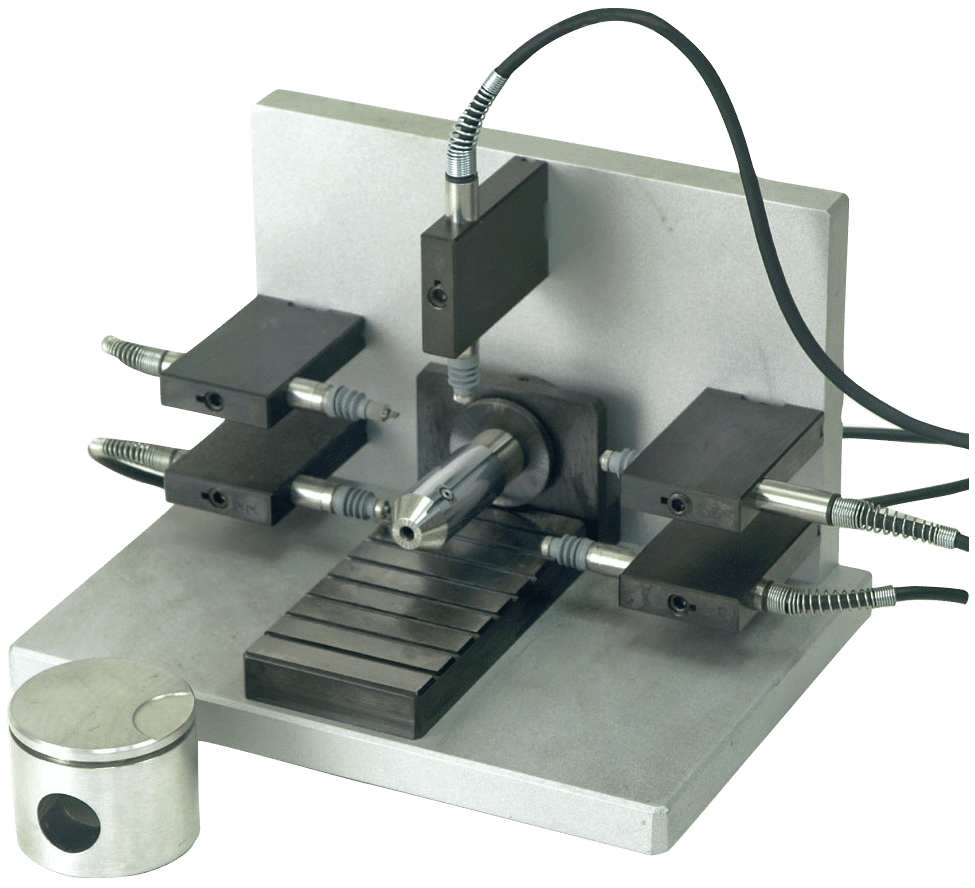

Piston Inspection Fixture utilizes LVDT probes to check O.D.s and Air Probes to check I.D.s

LVDT Gage & LVDT Readouts

Factory-installed interface modules operate LVDT type inductive probes.

Upper display shows ID, middle display shows OD and bottom display shows the calculated clearance between the parts.

LVDT sensors measure the voltage developed in wire coils as a magnetic core attached to a stylus is displaced by the test surface; changes in this voltage are displayed as dimensional changes.

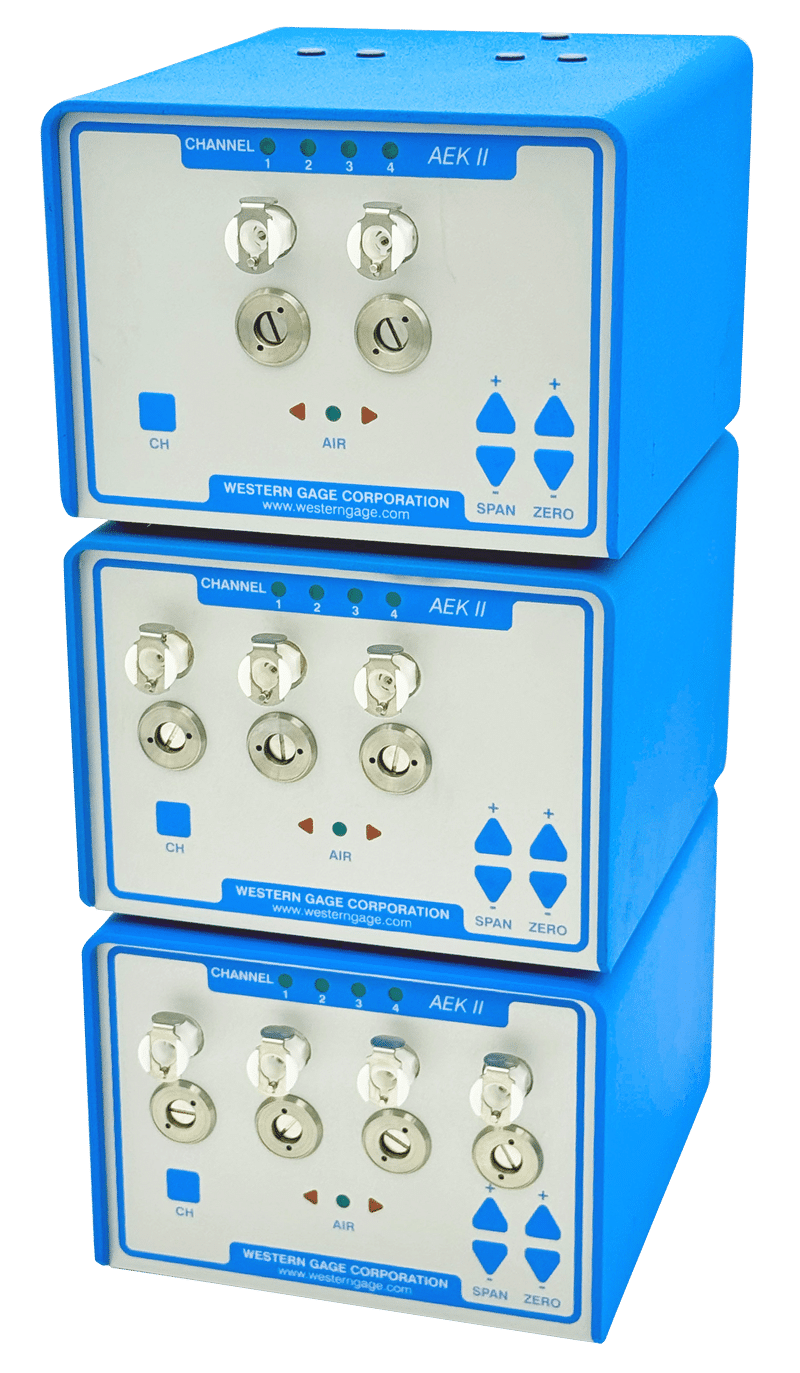

AEK II Air-Electric Converters & Metro M-400 Readouts

Model AEK II Air-Electric converters (right) coupled with Western Gage’s W-400 Readout (left) or PC Computer Gage Stations provide more computing capacity than Micro IIi readouts. These converters use the same proven air gage interface module as the Micro IIi Readout, each converter unit accommodates up to four analog and serial digital outputs in one shop hard housing. Multiple AEK converters can be stacked to accommodate complex applications.

Your W-400 gaging system uses the M400 readout to display dimensional characteristics of your workpiece. Most units are set up by Western Gage Corporation to be programmed and operational upon delivery. All accessories are available and included.

Readout / Comparator Options

Western Gage offers Readouts / Comparators in a wide range of display and input options.