MilliCheck & Micro IIi Readouts operate all popular makes of dual and single master type air gage members, as well as LVDT type electronic gages. Incorporating sealed controls, solid state pressure sensors, digital and bargraph LCD displays, these instruments perform exceptionally well on the shop floor as well as in metrology lab environments.

Air gage Readout Block Diagram

Air gage circuit – Pressure signals from solid state piezoresistive pressure transducers are sent to a microprocessor where the bargraph and digital display readings are calculated. Utilizing outputs from two transducers, one measuring the backpressure from the air gage nozzles, and one monitoring the regulator pressure, the microprocessor eliminates errors related to supply pressure variations. Being highly stable, Micro IIi & MilliCheck instruments can be operated using one or two setting masters. The adjustable flow restrictor incorporated in these instruments provides an exceptional range capability, accommodating gaging members with wide ranges of nozzle sizes and magnifications.

LVDT Readout Block Diagram

LVDT gage circuit – AC voltage is supplied to the LVDT gage sensors which return signals proportional to the displacement of the sensor styluses from their null voltage positions. The LVDT gage module processes the voltage from the sensors and directs the signal to the instrument’s microprocessor where the bargraph and digital display values are calculated. Polarity and Channel switches provide capability to sum or difference inputs from the sensors.

MilliCheck model AEC 30-10 with dual

master air probe and setting rings.

MilliCheck model AEC 30-E2 with

VeeCheck O.D. gage and setting master

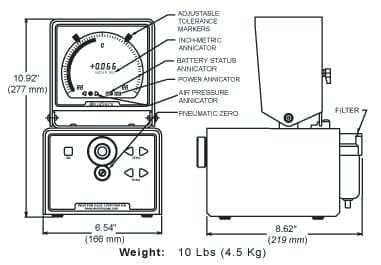

MilliCheck gage readouts feature high resolution LCD bargraphs and four decade digital displays. Designed for low power consumption, they operate from either standard “D” Cell batteries or AC power adapters. With user selectable multiple inch and metric gaging ranges, these readouts provide economical replacements for mechanical air gage instruments. They can be configured for either LVDT type electronic gages or air gages.

Millicheck Technical Data

Millicheck Technical Data

Bargraph display: Circular 121 Segment LCD

Digital display: 4 Decade LCD

Features, front panel:

Power-on

Zero adjust

Span adjust (dual master only)

Tolerance markers

Pneumatic Zero adjust (air gage modules only)

Air status indicator

Features, rear panel:

Inch – Metric selection

Operator front panel lockout

Auto on-off time select*

Input polarity

Scale selection (Field selectable scales are listed at the right.)

Gage inputs:

Select gage type listed below and add a suffix to order code as shown at the bottom of this page.

Series 10 Air gage — All dual master type air gages.

Series 60,70 or 80 Air gage — Single master type air gages.

E1, E2 or E3 High resolution LVDT — use on scale ranges ±.0015″ or ±.030 mm or less.

E4, E5, or E6 Extended range LVDT — Use on ranges ±.00075″ or ±.015 mm or greater.

Power:

Internal Battery*– 4 “D” cells

External power adapters, specify one:

110/125 VAC – 9 VDC, 60 Hz, adapter is standard.

100-240 VAC – 9VDC, 47-63 Hz, universal adapter with optional field changeable foreign outlet plugs.

Air gage module requirements:

.5 to 2 SCFM @ 40 to 125 psi (The actual air flow depends on nozzle sizes and gaging ranges of the air gage members connected to the readout).

* MilliCheck instruments incorporate an auto off mode to extend battery life.

Actuating the power button wakens the gage with no loss of calibration.

The auto-off mode can be turned off when operating from external power.

Millicheck Technical Data

Millicheck Technical Data