Specialty Dimensional Air Gages

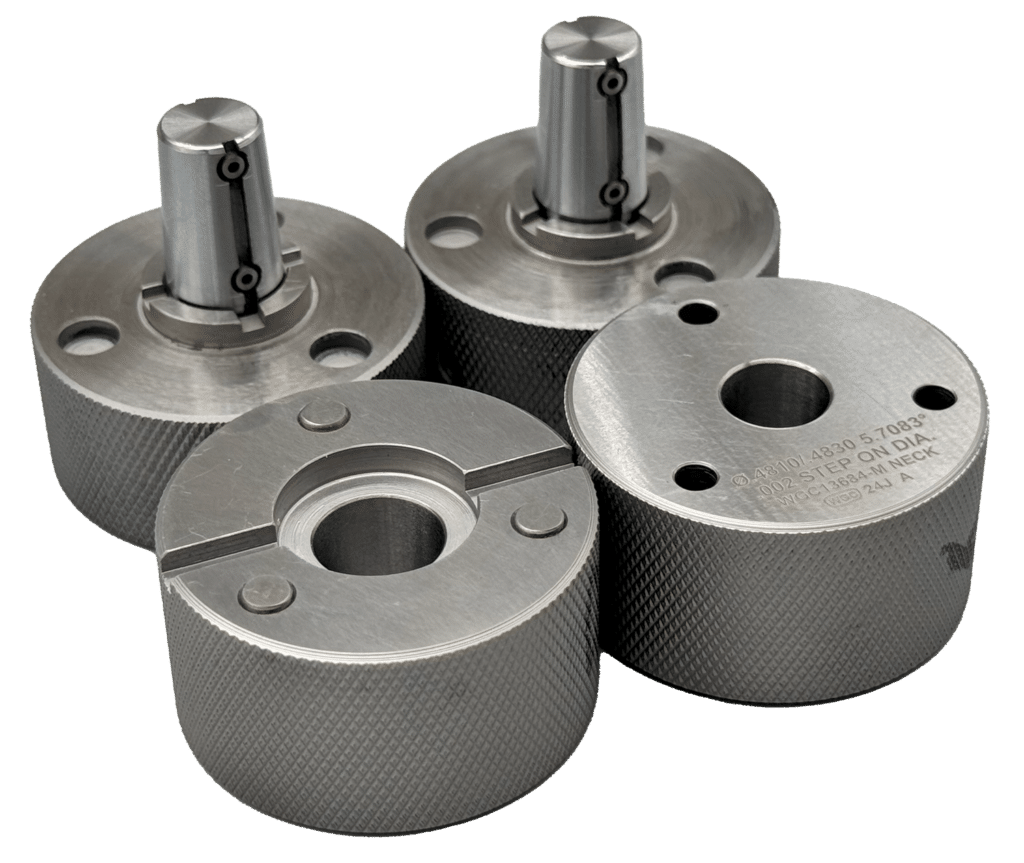

Cut-Out Shoulder Air Ring & Plug

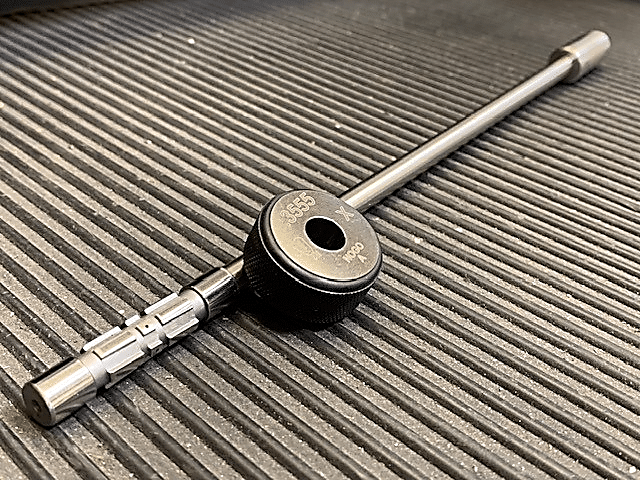

Taper Gage

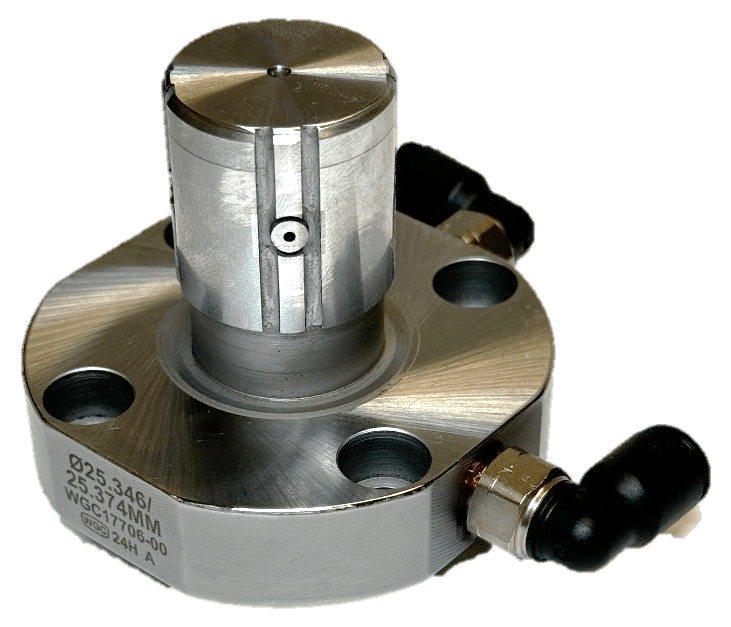

2-Circuit 2-Jet Air Spindle

Taper Knee Cap Gage

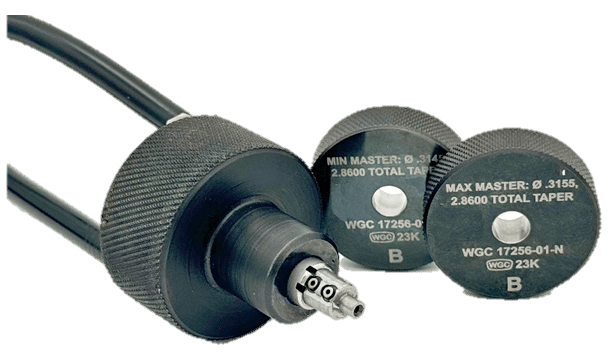

Custom Gage Samples

3-Circuit Two-Jet

Multi-Tiered Air Probe

Multi Circuit Probes, Base Mounted

Mounted Multi-Circuit Air Probe with Kevlar Front Bumper to prevent damaging parts

Rifling gages for gun barrels can precisely measure twists and bore diameters for various calibers and lengths.

Taper Air Probe with masters to measure press fit taper on femoral stems

How Does Air Gaging Work?

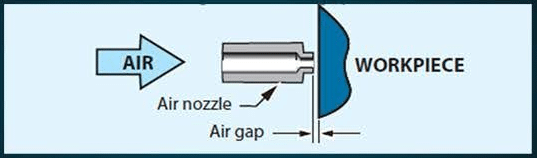

Air Gage Sensors measure the back pressure created when an air nozzle is brought in close proximity to the workpiece; the air gage readout measures this pressure and displays the dimensional change in the air gap.

Air Gage Sensors are non-contact. Wear does not directly affect the accuracy of the gage and has a self cleaning effect on the workpiece ideal for shop floor environments.

Air Nozzles can be made with jet holes from .010″ to .100″ (.25 to 2.54 mm), with .050″ (1.25 mm) being preferred for most applications.

Below we have examples of Standard Air Probes, Dimensional Air Gage Options, and Custom Gage Samples